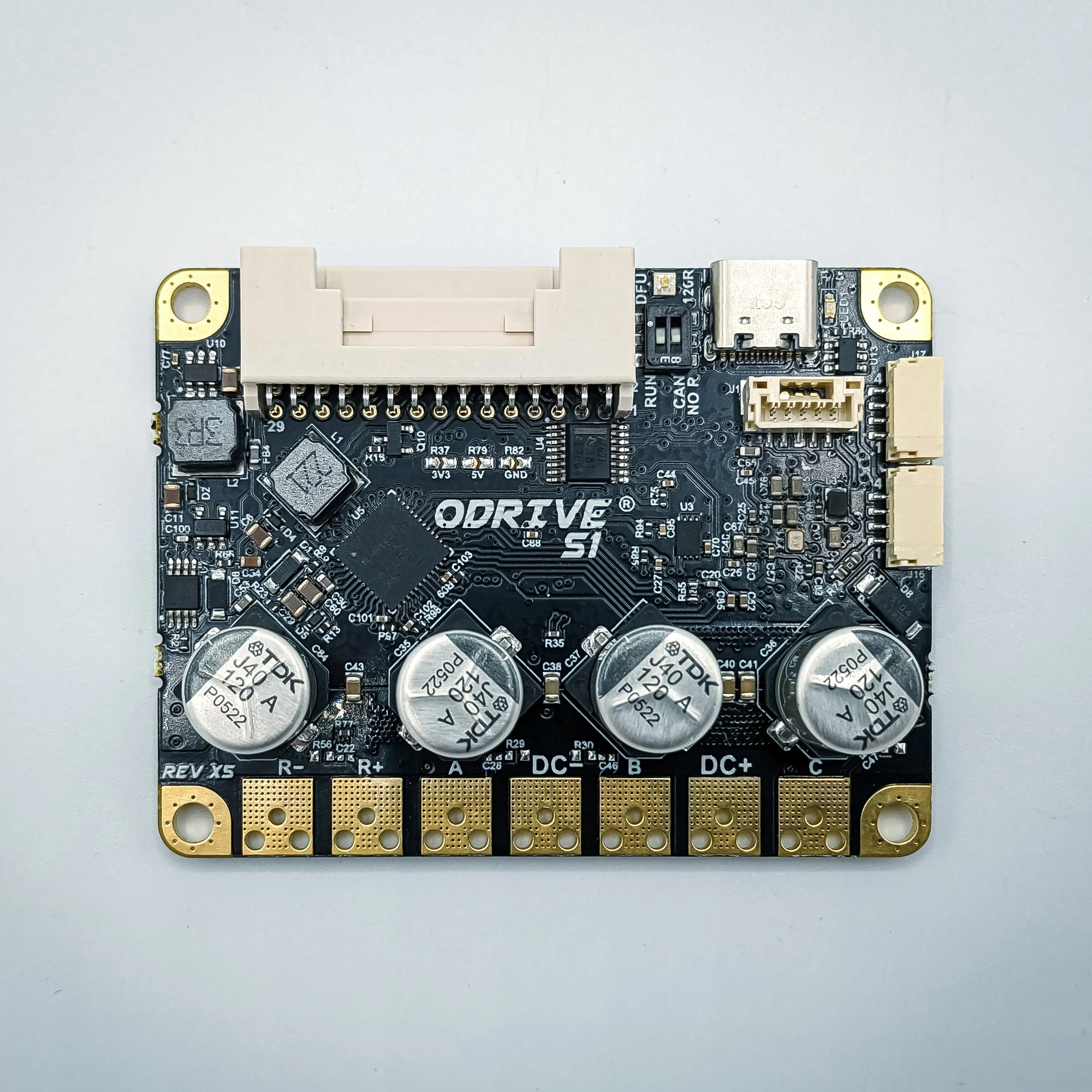

ODrive S1

ODrive S1

Shown with a heat spreader plate: recommended, sold separately.

Comes with a 2ohm 50W power resistor.

Locking IO connectors usable with Breakout Harness, Harness Build Kit and CAN cables.

Browse encoders, motors and accessories that go with ODrive S1.

USB and DC input may not be connected at the same time, unless you use a USB isolator.

Datasheet - CAD - Software Documentation - Configuration GUI

Specifications Below

SKUs:

- With screw terminal: ODS1-ST

- Without screw terminal: ODS1

1 - $ 149.00

10 - $ 147.00

For 40+ please use the RFQ/Order form.

40 - $ 145.00

100 - $ 143.00

For larger volumes please contact us for OEM pricing.

The ODrive S1 brings the next generation ODrive ecosystem to every robot, with:

Locking connector for easy wire harness design and assembly

On-board brake chopper manages brake energy using a brake resistor.

Dual absolute encoder support allows for precise load positioning and instant cold starts

Shares software architecture with ODrive Pro, including Web GUI support

Customization, integration and licencing available

Features & Specs

Single-axis (controls 1 motor)

High performance servo control of BLDC and PMAC motors

Torque, velocity, position, and trajectory control modes

Sensorless speed control

12-48V Operation (50.5V max)

40A Continuous (with heat spreader, recommended)

Control over USB, UART (Isolated), STEP/DIR (Isolated), Analog Voltage, PWM, and CAN

Electrical Features

On-board brake resistor chopper

Built-in motor thermistor divider circuit

CAN 2.0B @ 1Mbps Control (CAN-FD Firmware Coming Soon)

On-board magnetic encoder: MA702

High quality encoder magnet available here. Recommended gap to top of package: 1mm

Supports offboard quadrature, hall, SPI, and RS485 encoders

Incremental encoders and hall sensors have on-board input filters

Isolated Step/Direction and UART Controls

Large IO connector with a diverse and flexible feature set.

Mechanical Specifications

Mass - 35g (no screw terminal) | 55g (screw terminals present)

Board Perimeter - 66mm x 50mm

Single locking connector for IO & Feedback

Controls Specifications

24kHz PWM frequency

8kHz control loop frequency (24kHz current control loop coming soon)

700Hz max recommended electrical frequency (2000Hz support coming soon)